- mahaco

- CHINA

- 7 days

- 3000tons/month

Fluoride & Arsenic Removal: The leading adsorbent for water treatment, effectively removing fluoride, arsenic, and other contaminants from drinking water.

Acid Gas Removal: Acts as an adsorbent for acid gas removal, capturing HCl, HF, and SOx from process streams in chemical and petrochemical plants.

Liquid & Gas Purification: Removes impurities and polar compounds from organic liquids, solvents, and various industrial gas streams.

Activated Alumina Adsorbent in air separation (A-AS-A)

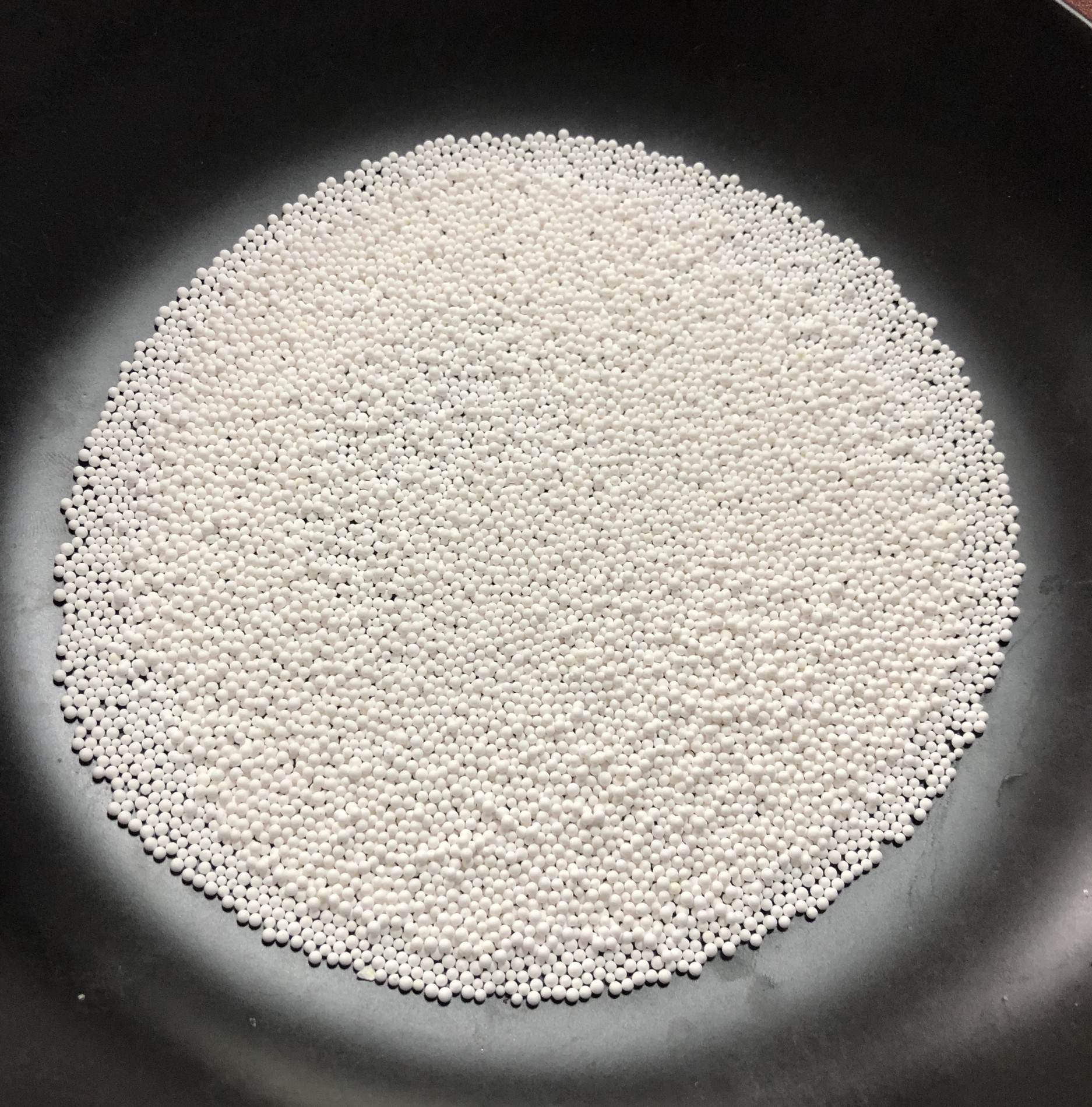

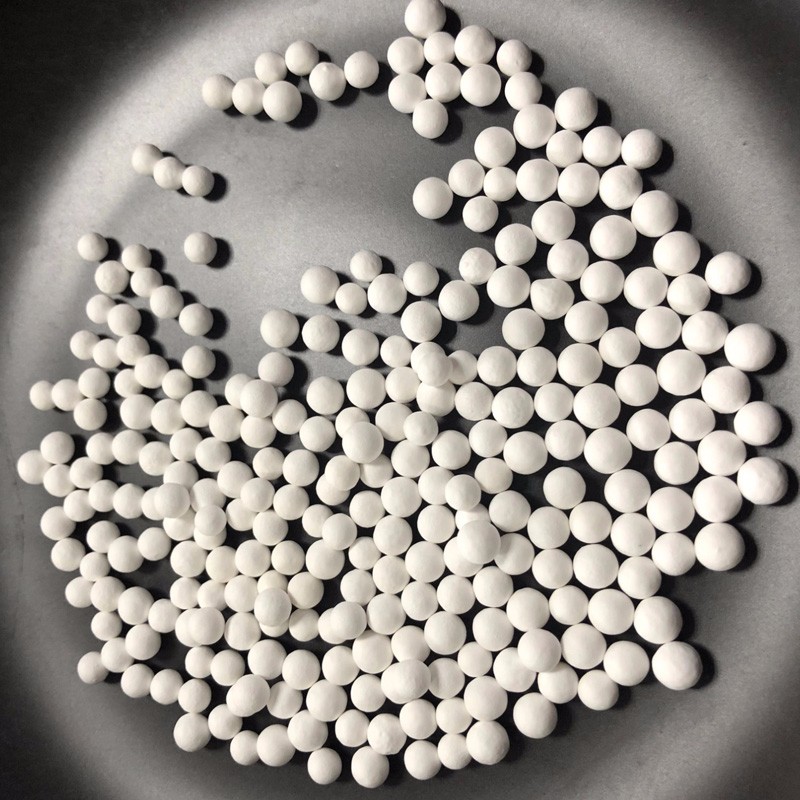

This line of products features high crush strengths and low dust content. The material is highly porous, can have a surface area greater than 330 m2/g, and can achieve dew points of -40°F to -100˚F, depending on operating conditions and the design of the dryer.

Features of activated alumina:

Low Dust

Low Attrition

High Crush Strength

Uniform Bead Size

High Adsorption Capacity

Activated alumina is often used in the following applications:

Compressed air drying

Natural gas drying

Removal of acids from transformer oils, lubricating oils, and refrigerant

Technical Property of Activated Alumina

| Type Item | A-AS-04 Absorbent | A-AS-DF Defluoridizer | A-AS-MS Absorbent for H2O2 | A-AS-AC Antichlor | A-AS-C Catalyst carrier | A-AS-A Absorbent in air separation | |||

| Appearance | White ball | ||||||||

| Main crystal phase | χ-ρ | χ-ρ | γ | χ-ρ | γ | χ-ρ | |||

Chemical composition % | Al2O3 | ≥93 | ≥93 | ≥92 | ≥90 | ≥93 | ≥90 | ||

| Na2O | ≤0.3 | ≤0.3 | ≤0.5 | 0.15-0.3 | ≤0.3 | ||||

| I.L | 6-8 | 6-8 | ≤8 | ≤ | ≤5 | 6-8 | |||

| Bulk density,g/ml | 0.68-0.72 | 0.70-0.75 | 0.65-0.75 | 0.68-0.78 | 0.70-0.80 | 0.68-0.72 | |||

| Surface area,m2/g | ≥280 | ≥280 | 200-260 | ≥300 | ≥200 | ≥300 | |||

| Pore volume,ml/g | 0.3-0.45 | 0.3-0.42 | 0.4-0.46 | 0.3-0.5 | 0.4 | 0.3-0.5 | |||

| Static absorption,% | Water 20 | Fluorin 0.12 | Water 50 | Chlorine 10-20 | Water 50-70 | Water 20 | |||

| Activity,% | - | - | 56-62 | - | - | - | |||

| Loss on abrasion,% | ≤1.0 | ≤1.0 | ≤1.0 | ≤0.7 | ≤0.4 | ≤0.8 | |||

| Crushing strength, N/grain | Φ1-2 | ≥40 | ≥40 | - | ≥40 | - | - | ||

| Φ2-3 | ≥60 | ≥60 | - | - | - | - | |||

| Φ3-5 | ≥100 | - | ≥100 | ≥82 | ≥100 | ≥100 | |||

| Φ4-6 | ≥120 | - | ≥130 | ≥120 | ≥120 | ≥110 | |||

| Φ5-7 | ≥120 | ≥150 | ≥150 | ≥150 | ≥160 | ≥150 | |||

| Φ6-8 | ≥200 | ≥200 | ≥200 | ≥200 | ≥220 | ≥200 | |||

The products in other types or sizes can also be manufactured if to the user's request.

Application

A-AS-04 activated alumina is manufactured from aluminium hydroxide by dehydroxylating it in a way that produces a highly porous material;

A-AS-DF activated alumina is also widely used to remove fluoride from drinking water. Basically, the more alumina in the filter, the less fluoride will be in the final, filtered water.

A-AS-MS is for absorbent H2O2

A-AS-AC is for chlorine absorbent

A-AS-C in hydrogen peroxide production, as a selective adsorbent for many chemicals including, in removal from gas streams .

A-AS-A activated alumina is used as a charge material in foreline traps to prevent generated by from backstreaming into the system

Industry standard HG/T39272007 Activated Alumina is issued by Zhengzhou Mahaco Industrial Co,Ltd

Activated Alumina: The Versatile Desiccant, Adsorbent, and Catalyst Support

ZHENGZHOU MAHACO INDUSTRIAL CO., LTD. is a premier manufacturer of high-performance Activated Alumina, a multifunctional material engineered to excel in three critical industrial roles: as a powerful desiccant, a selective adsorbent, and a stable catalyst support. Our activated alumina balls deliver unmatched reliability in moisture removal, impurity purification, and catalytic processes across diverse sectors.

1. Superior Industrial Desiccant

As a high-capacity activated alumina desiccant, our product is the preferred choice for deep drying applications due to its exceptional moisture adsorption, thermal stability, and regeneration capability.

Primary Applications:

Compressed Air & Gas Drying: The ideal desiccant for compressed air dryers (heatless, heated, and blower purge types), ensuring instrument-quality air by achieving dew points as low as -70°C.

Petrochemical Drying: Used extensively as a deep bed desiccant for drying liquid and gaseous hydrocarbons (e.g., LPG, natural gas, reformer feeds) to prevent pipeline corrosion and freezing.

Insulating Glass: Serves as a key desiccant for insulating glass units, absorbing residual moisture between panes to prevent fogging.

Key Advantage: Exceptional crush strength withstands high pressure in deep beds, and its ability to be regenerated multiple times offers a superior lifetime value.

2. High-Efficiency Adsorbent

Beyond moisture, our activated alumina adsorbent selectively removes a wide range of impurities from gases and liquids through surface adsorption and pore filtration.

Primary Applications:

Fluoride & Arsenic Removal: The leading adsorbent for water treatment, effectively removing fluoride, arsenic, and other contaminants from drinking water.

Acid Gas Removal: Acts as an adsorbent for acid gas removal, capturing HCl, HF, and SOx from process streams in chemical and petrochemical plants.

Liquid & Gas Purification: Removes impurities and polar compounds from organic liquids, solvents, and various industrial gas streams.

3. Reliable Catalyst Support (Carrier)

The high surface area, inert nature, and thermal stability of our activated alumina balls make them an excellent catalyst support material (or carrier) for numerous chemical reactions.

Primary Applications:

Petrochemical & Refining: Widely used as a catalyst support in hydrogen peroxide production, Claus catalyst for sulfur recovery, and in various hydrotreating and reforming processes.

Chemical Synthesis: Provides a stable, porous base for catalysts used in polymerization, dehydration, and other catalytic reactions.

Automotive: Used as a carrier in some automotive catalyst systems.

Key Advantage: Our alumina provides optimal pore structure, strong metal-catalyst binding, and resilience under high-temperature and high-pressure conditions, ensuring catalyst effectiveness and longevity.

Why Source from ZHENGZHOU MAHACO?

Tri-Function Expertise: We understand the precise properties required for each role—desiccant, adsorbent, and catalyst support—and tailor our product specifications accordingly.

Customized Solutions: Available in various sizes (e.g., 1-3mm, 3-5mm, 4-6mm, 5-8mm), shapes (balls, pellets), and with controlled surface area/pore size to match your specific process.

Consistent Quality & Supply: Rigorous production controls ensure high purity, consistent performance, and reliable supply for your continuous operations.

Technical Support: Our team provides expert guidance on selection, regeneration procedures, and system design.

Packaging: Standard 25kg bags or 1-ton jumbo bags, with custom packaging available.

Unlock Process Efficiency with One Versatile Material

Whether your priority is achieving extreme dryness, purifying a process stream, or supporting a critical catalyst, ZHENGZHOU MAHACO’s Activated Alumina provides a robust and cost-effective solution. As a trusted activated alumina manufacturer and supplier, we are committed to supporting your industrial success.

Contact us today to discuss your application needs, request technical data sheets, or get a quotation for your desiccant, adsorbent, or catalyst support requirements. Let our expertise enhance your process.