How Do Aluminium Potassium Sulphate Crystals Benefit Paper Manufacturing

The paper manufacturing industry has evolved significantly over the past decades, with continuous innovations in raw materials and processing techniques. Among the many chemicals used, aluminium potassium sulphate crystals have emerged as a cornerstone for enhancing paper quality and production efficiency. Zhengzhou Mahaco Industrial Co.,Ltd (MAHACO), a leading supplier of industrial chemicals, provides in-depth expertise on the benefits and applications of these crystals in modern paper mills.

Understanding Aluminium Potassium Sulphate Crystals

Aluminium potassium sulphate, commonly known as potash alum, is a double sulphate salt with the chemical formula KAl(SO4)2·12H2O. Its crystalline form is widely recognized for its purity, stability, and versatility in industrial applications. In paper manufacturing, these crystals play a pivotal role in several stages, particularly in sizing and water purification.

trusted china manufacturer for high quality sulfamic acid powder

nsf certified poly aluminium chloride pac

sodium hexametaphosphate shmp flake

MAHACO sources and supplies high-grade aluminium potassium sulphate crystals, ensuring consistent quality for clients across the globe. Their expertise extends to advising on optimal dosages and integration methods, which is critical for achieving desired paper characteristics and minimizing production costs.

The Role of Aluminium Potassium Sulphate Crystals in Paper Manufacturing

Paper Sizing: The addition of aluminium potassium sulphate crystals during the sizing process helps control the absorbency of paper. By reacting with rosin, these crystals form a hydrophobic layer that imparts resistance to water and ink, making paper suitable for printing and writing applications.

Water Treatment: Effective water purification is essential for high-quality paper production. Aluminium potassium sulphate acts as a coagulant, removing suspended particles and organic impurities from process water, thereby ensuring a cleaner and more consistent pulp.

pH Adjustment: Maintaining the correct pH is crucial for paper strength and brightness. The acidic nature of aluminium potassium sulphate helps regulate pH levels, preventing undesirable chemical reactions that could compromise paper quality.

MAHACO’s technical team collaborates with paper mills to optimize the use of these crystals, tailoring solutions to specific production requirements. This partnership approach not only enhances product quality but also supports environmental compliance through efficient chemical usage.

Industry Trends: aluminium sulphate granules and Non Ferric Aluminium Sulphate

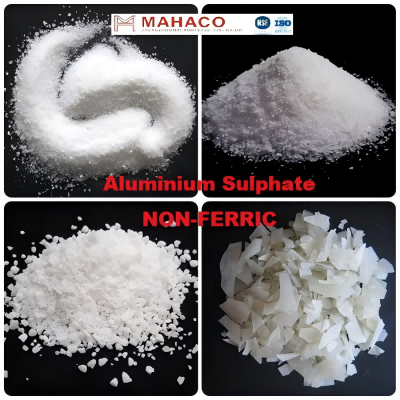

While aluminium potassium sulphate crystals remain a staple, the industry is also witnessing a growing demand for aluminium sulphate granules and non ferric aluminium sulphate. These variants offer unique benefits for paper manufacturers:

Aluminium Sulphate Granules: Favored for their ease of handling and rapid dissolution, granules facilitate streamlined dosing and uniform distribution in pulp mixtures. MAHACO’s granules are engineered for minimal dust generation, improving workplace safety and reducing waste.

Non Ferric Aluminium Sulphate: With low iron content, non ferric grades are ideal for producing high-brightness paper. They minimize discoloration and enhance the visual appeal of finished products, a critical factor for premium writing and printing papers.

MAHACO continues to expand its portfolio, providing tailored solutions that address the evolving needs of the paper industry. Their commitment to quality and innovation is reflected in the growing adoption of these advanced chemical forms.

Expanding Horizons: Sustainability and Technological Advancements

The paper manufacturing sector is increasingly focused on sustainability and environmental stewardship. Chemicals like aluminium potassium sulphate crystals contribute to these goals by enabling efficient water treatment and reducing the need for harmful additives. MAHACO is at the forefront of promoting green practices, offering eco-friendly formulations and supporting recycling initiatives within paper mills.

Technological advancements are also shaping the future of paper production. Automated dosing systems, real-time process monitoring, and data-driven optimization are becoming standard features in modern facilities. MAHACO invests in research and development to align its products with these trends, ensuring seamless integration and superior performance.

Expert Commentary: Why Choose MAHACO for Your Chemical Needs?

As a trusted partner to the global paper industry, MAHACO distinguishes itself through rigorous quality control, responsive customer service, and comprehensive technical support. Their team of specialists assists clients in selecting the most suitable chemicals, whether it’s traditional aluminium potassium sulphate crystals, innovative aluminium sulphate granules, or non ferric aluminium sulphate for specialized applications.

Clients benefit from MAHACO’s extensive logistics network, ensuring timely delivery and consistent supply, even in challenging market conditions. The company’s commitment to transparency and sustainability further strengthens its reputation as a reliable supplier.

Conclusion: The Future of Paper Manufacturing with MAHACO

Aluminium potassium sulphate crystals are indispensable in modern paper manufacturing, offering unmatched benefits in sizing, water treatment, and pH control. With the emergence of aluminium sulphate granules and non ferric aluminium sulphate, manufacturers now have access to a broader range of solutions for enhancing paper quality and production efficiency.

Zhengzhou Mahaco Industrial Co.,Ltd (MAHACO) remains a leader in supplying these essential chemicals, driving innovation and sustainability across the industry. As paper mills embrace new technologies and green practices, the role of high-quality chemical inputs will only become more critical. For manufacturers seeking to stay ahead, partnering with MAHACO is a strategic choice for long-term success.