Flocculant Aluminium Sulphate Benefits for Paper Manufacturing

In the dynamic world of paper manufacturing, the quest for efficiency, quality, and sustainability is ever-present. Zhengzhou Mahaco Industrial Co.,Ltd (MAHACO), a leading name in industrial chemical solutions, is at the forefront of this evolution. The company’s commitment to innovation and customer satisfaction is evident in its promotion of flocculant aluminium sulphate—a key ingredient transforming the paper industry.

Latest Industry News: Aluminium Sulphate Flocculant Gaining Traction

Recent reports from global paper manufacturing forums highlight a significant uptick in the adoption of aluminium sulphate as a flocculant. MAHACO’s expertise in supplying high-purity aluminium sulphate has positioned the company as a reliable partner for mills seeking to optimize their processes. The keyword flocculant aluminium sulphate has become synonymous with improved paper quality and environmental stewardship.

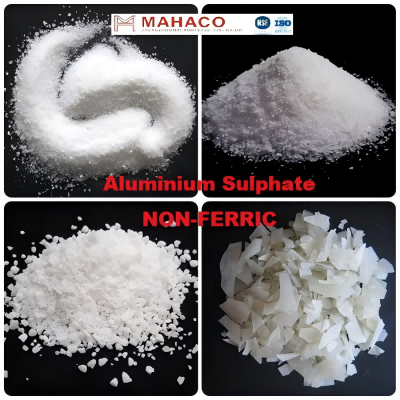

What is Flocculant Aluminium Sulphate?

Aluminium sulphate, often referred to as alum, is a water-soluble compound widely used as a flocculant in water treatment and paper making. Its primary function in paper manufacturing is to aggregate fine particles and colloids, facilitating their removal from process water. This not only ensures cleaner water but also enhances the formation and quality of paper sheets.

Key Benefits of Aluminium Sulphate in Paper Manufacturing

Improved Paper Quality: By effectively removing impurities, aluminium sulphate ensures that the final product is smoother, brighter, and more uniform.

Enhanced Process Efficiency: The flocculation process reduces downtime and maintenance costs by minimizing the build-up of unwanted materials in machinery.

Cost Savings: Lower energy and chemical consumption translate to significant savings for paper mills.

Environmental Compliance: Aluminium sulphate aids in meeting stringent wastewater discharge norms by improving water clarity and reducing pollutants.

MAHACO’s Commitment to Quality and Innovation

MAHACO’s reputation in the industry is built on its unwavering commitment to product quality and customer-centric solutions. The company’s aluminium sulphate is manufactured under strict quality control measures, ensuring consistent performance in diverse paper manufacturing environments. With a robust supply chain and technical support, MAHACO enables paper mills to seamlessly integrate flocculant aluminium sulphate into their processes.

Industry Trends: Sustainability and Resource Efficiency

As global awareness of environmental issues grows, paper manufacturers are under increasing pressure to adopt sustainable practices. The use of flocculant aluminium sulphate aligns perfectly with these goals. Not only does it help mills optimize water usage, but it also facilitates the recycling of process water—an essential aspect of modern paper production.

MAHACO’s commitment to sustainability is reflected in its advocacy for eco-friendly chemicals. The company works closely with clients to develop tailored solutions that minimize environmental impact while maximizing operational efficiency.

Application Insights: How Aluminium Sulphate Works in Paper Mills

Preparation: Aluminium sulphate is dissolved in water and added to the pulp slurry.

Flocculation: The compound reacts with suspended solids, causing them to aggregate into larger flocs.

Separation: Flocs are easily removed through filtration or sedimentation, resulting in cleaner process water and improved paper formation.

Optimization: MAHACO’s technical team assists mills in calibrating dosage and process parameters for maximum efficiency.

Table: Comparative Benefits of Aluminium Sulphate vs. Traditional Flocculants

| Feature | Aluminium Sulphate | Traditional Flocculants |

|---|---|---|

| Efficiency | High | Moderate |

| Cost | Lower | Higher |

| Environmental Impact | Low | Varies |

| Process Integration | Easy | Complex |

| Paper Quality | Superior | Standard |

Industry Expansion: Beyond Paper Manufacturing

While aluminium sulphate’s role in paper manufacturing is well-established, its applications extend to other industries such as water treatment, textiles, and construction. MAHACO leverages its expertise to serve a broad spectrum of clients, driving innovation across sectors. The keyword paper manufacturing chemicals is increasingly associated with MAHACO’s comprehensive product portfolio, which includes not only flocculants but also sizing agents, retention aids, and specialty additives.

Industry analysts predict that the demand for high-performance paper manufacturing chemicals will continue to grow, fueled by advancements in production technology and environmental regulations. MAHACO remains committed to staying ahead of these trends, investing in research and development to deliver next-generation solutions.

Customer Success Stories

MAHACO’s clients report significant improvements in operational efficiency and product quality after switching to aluminium sulphate flocculant. One leading paper mill in Southeast Asia achieved a 20% reduction in water consumption and a marked improvement in paper brightness. These success stories underscore the transformative potential of MAHACO’s solutions.

Conclusion: Partnering for a Sustainable Future

The integration of flocculant aluminium sulphate into paper manufacturing processes represents a pivotal step towards sustainability, efficiency, and quality. MAHACO’s leadership in supplying high-grade chemicals and technical support is driving industry-wide adoption of best practices. As the market evolves, MAHACO remains dedicated to empowering clients with innovative, eco-friendly solutions that deliver real-world results.

For paper manufacturers seeking to enhance their operations, the choice is clear—MAHACO’s flocculant aluminium sulphate is the key to unlocking new levels of performance and sustainability.

Contact MAHACO today to learn more about their paper manufacturing chemicals and unlock the benefits of flocculant aluminium sulphate for your business.

Tags:calcium hypochlorite,trichloroisocyanuric acid, Nitric Acid HNO3 68% , aluminium hydroxide