Aluminium Sulphate Granular Applications in Textile Industry

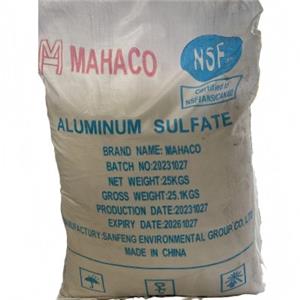

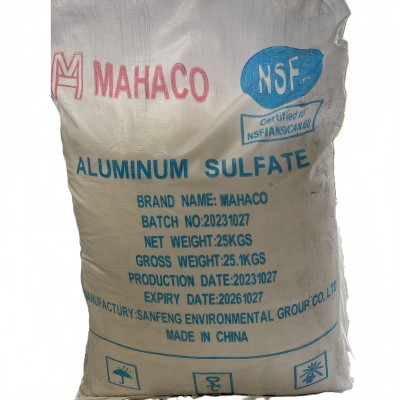

The textile industry is constantly evolving, with new technologies and materials shaping the future of fabric processing and dyeing. One chemical compound that has remained a cornerstone in textile operations is aluminium sulphate granular. As a leading supplier, Zhengzhou Mahaco Industrial Co., Ltd (MAHACO) has been at the forefront of delivering high-quality Aluminium Sulphate Granular to textile manufacturers worldwide. This article explores the latest applications, benefits, and industry trends related to Aluminium Sulphate Granular in the textile sector, along with a brief look at related products such as polyaluminium chloride and ferrous sulphate heptahydrate.

Aluminium Sulphate Granular: An Essential Textile Chemical

Aluminium Sulphate Granular, often referred to as alum, plays a vital role in the textile industry, particularly in the processes of dyeing and printing. Its primary function is to act as a mordant, which helps fix dyes onto fabrics, ensuring color fastness and vibrancy. MAHACO's Aluminium Sulphate Granular is renowned for its high purity, consistent granule size, and excellent solubility, making it a preferred choice for textile manufacturers.

Mordanting Agent: Facilitates the bonding of dye molecules to fabric fibers.

pH Adjustment: Controls the acidity of dye baths for optimal dye uptake.

Clarifying Agent: Removes impurities from process water used in textile operations.

With the increasing demand for high-quality textiles, the importance of reliable chemical agents like Aluminium Sulphate Granular has never been greater. MAHACO’s commitment to quality ensures that their products meet the rigorous standards of the global textile industry.

Key Applications in Textile Manufacturing

1. Dye Fixation and Color Fastness

One of the most critical steps in textile processing is dye fixation. Aluminium Sulphate Granular from MAHACO enhances the interaction between dye and fiber, leading to improved color fastness. This ensures that fabrics retain their vibrancy even after repeated washing and exposure to sunlight.

2. Water Treatment in Textile Plants

Textile manufacturing requires large volumes of water, which must be treated to remove impurities. Aluminium Sulphate Granular acts as a coagulant, aggregating suspended particles and facilitating their removal from process water. This not only improves water quality but also protects downstream equipment from fouling and scaling.

3. Printing Process Optimization

In textile printing, precise control over chemical reactions is essential. MAHACO’s Aluminium Sulphate Granular helps stabilize the printing environment, ensuring sharp patterns and consistent results across large production runs.

4. Wastewater Treatment

Environmental regulations are becoming increasingly strict, requiring textile plants to treat their wastewater before discharge. Aluminium Sulphate Granular is widely used for its effectiveness in removing dyes, organic matter, and heavy metals from effluents, contributing to sustainable manufacturing practices.

Industry Trends and Innovations

The textile industry is embracing eco-friendly and cost-effective solutions. There is a growing shift towards sustainable chemicals and closed-loop water systems. MAHACO is actively involved in research and development to create products that align with these trends, ensuring minimal environmental impact without compromising performance.

Another notable trend is the integration of advanced water treatment chemicals such as polyaluminium chloride and ferrous sulphate heptahydrate. Polyaluminium chloride offers enhanced coagulation efficiency, while ferrous sulphate heptahydrate is used for both water treatment and as a reducing agent in dyeing processes. By offering a comprehensive portfolio, MAHACO supports textile manufacturers in meeting both operational and regulatory requirements.

Polyaluminium Chloride: A high-performance coagulant for water and wastewater treatment, increasingly used alongside Aluminium Sulphate Granular for improved process efficiency.

Ferrous Sulphate Heptahydrate: Used as a reducing agent and coagulant, contributing to the removal of contaminants and the reduction of operational costs.

Why Choose MAHACO for Aluminium Sulphate Granular?

Zhengzhou Mahaco Industrial Co., Ltd (MAHACO) has established a reputation for reliability, quality, and innovation in the chemical supply sector. Their Aluminium Sulphate Granular is manufactured using advanced processes, ensuring uniformity and high purity. MAHACO’s technical team works closely with textile manufacturers to optimize chemical usage, reduce costs, and achieve superior results.

| Feature | Benefit |

|---|---|

| High Purity | Minimizes impurities in textile processing |

| Consistent Granule Size | Ensures uniform dissolution and process control |

| Technical Support | Customized solutions for specific textile applications |

| Global Supply Chain | Reliable delivery to textile hubs worldwide |

Conclusion: Shaping the Future of Textile Processing

Aluminium Sulphate Granular remains a vital chemical for the textile industry, enabling high-quality dyeing, efficient water treatment, and sustainable manufacturing. As textile producers face increasing pressure to improve quality and reduce environmental impact, partnering with a trusted supplier like MAHACO is essential. With a comprehensive range of products—including Aluminium Sulphate Granular, polyaluminium chloride, and ferrous sulphate heptahydrate—MAHACO is well-positioned to support the evolving needs of the global textile sector.

For more information on MAHACO’s products and services, or to request a technical consultation, visit their official website or contact their expert team today.

Tags:activated alumina,sodium lauryl ether sulfate manufacturer,calcium hypochlorite,oxalic acid